Learn and get Certified for SAP PP

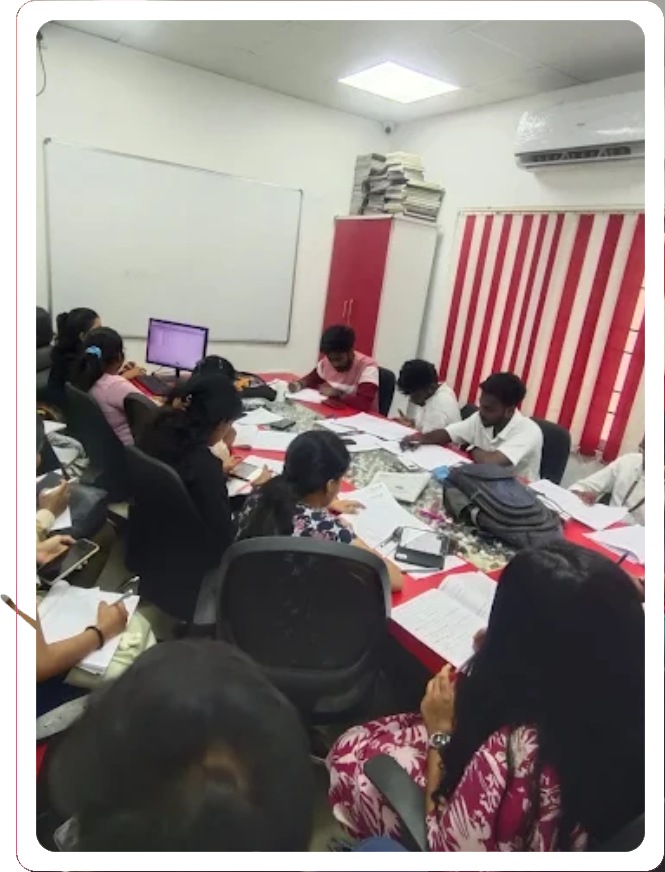

Learning SAP PP at TechMaax equips you with the skills to manage production planning and manufacturing processes within SAP. Through hands-on training and real-world scenarios, you’ll gain expertise in material requirements planning, production scheduling, and shop floor control, preparing you for a successful career in manufacturing operations and enterprise resource planning.

WHY LEARN SAP PP?

Master production planning and manufacturing processes in SAP.

SAP PP (Production Planning) is a core module in SAP that helps organizations plan, manage, and control their manufacturing and production processes efficiently. It integrates material management, sales, and distribution with production operations, ensuring optimized resource utilization and smooth workflow across the supply chain.

At TechMaax, the SAP PP program is designed to help learners master production planning and control through practical, real-time training. The course covers everything from demand management and bill of materials to production scheduling and capacity planning. Guided by expert trainers, students gain hands-on experience with SAP PP tools used by leading enterprises, preparing them for rewarding careers in manufacturing, operations, and ERP implementation.

Learn about the curriculum of SAP PP by clicking on the button below.

SAP PP

Key HIGHLIGHTS of SAP PP

Recognized Certification

TechMaax offers globally recognized certifications that validate your skills and enhance your professional credibility worldwide.

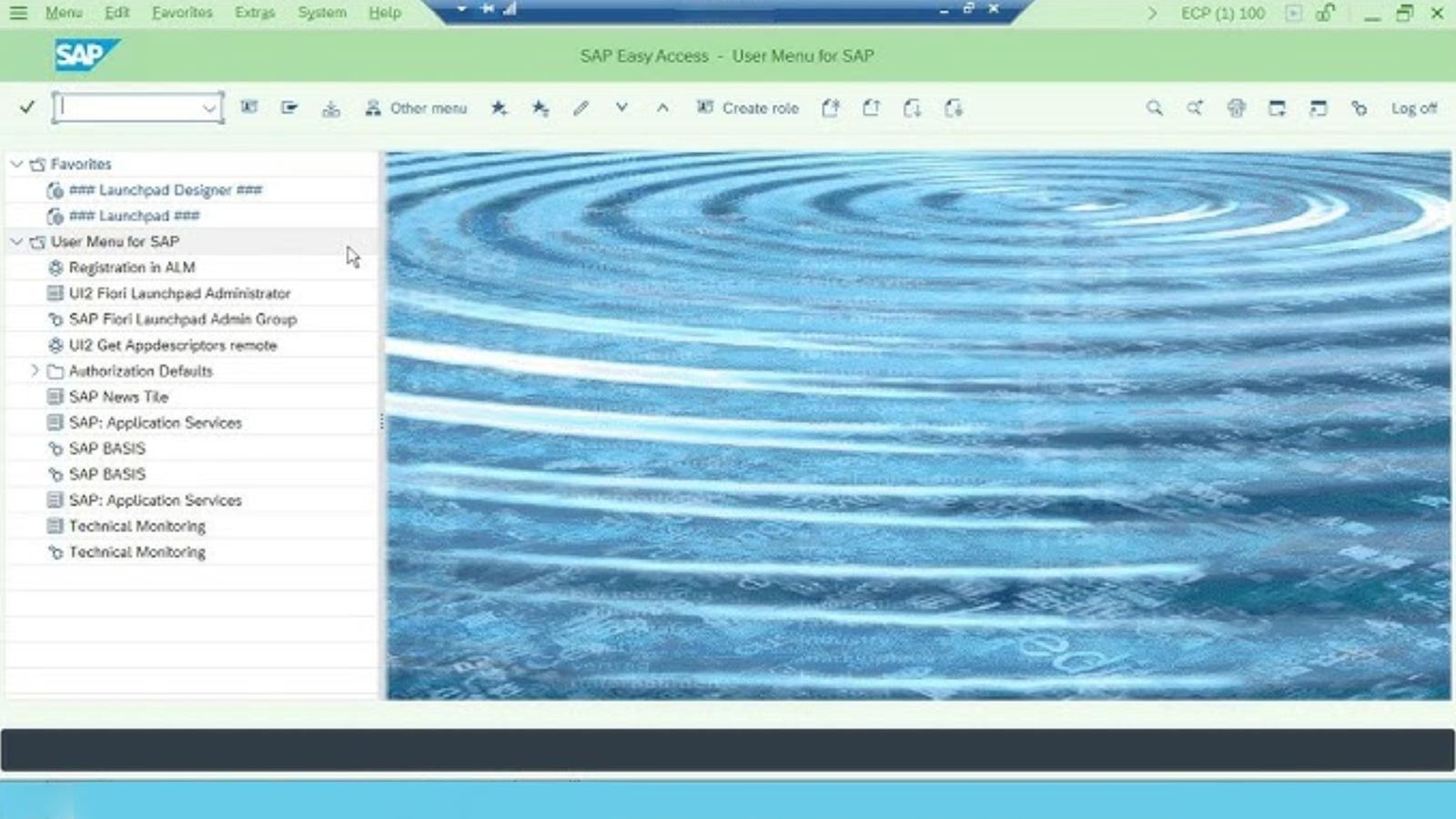

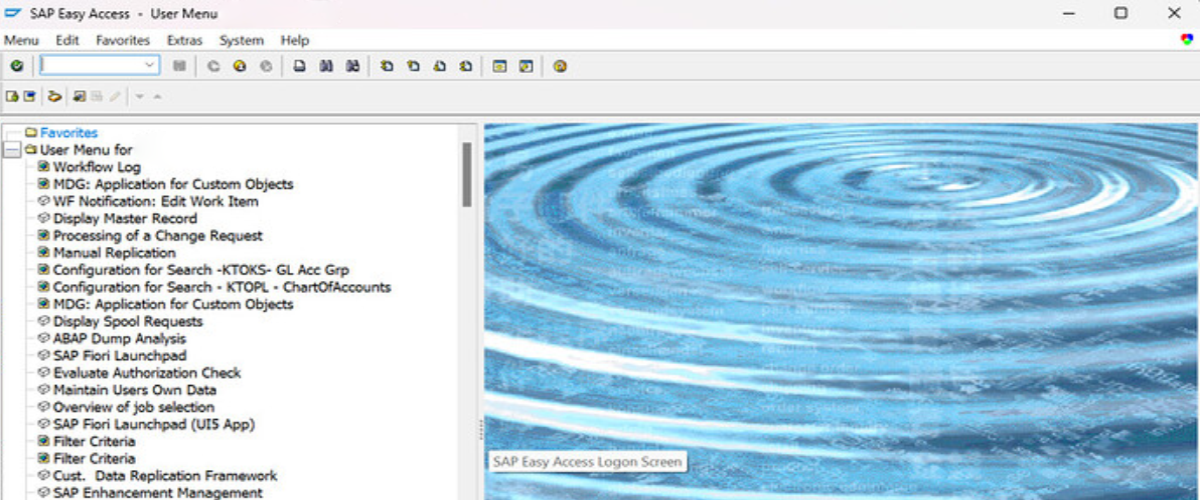

Hands-On Training

The training environment replicates real business scenarios, allowing students to work on production planning, material requirements, scheduling, and shop control processes directly in SAP PP.

For Production Planners

SAP PP is ideal for students, production planners, manufacturing professionals, and supply chain specialists who want to build expertise in production planning and streamline manufacturing operations within SAP.

Certification Price

Rs. 25,000

- Global SAP Certificate

- Duration of 1 to 3 months

- Offline/Online Mode

- Recording Backup Available

- Student Friendly Faculties

- Hands-on Training

- Placement Assistance

HOW TO START

Begin in Three Simple Steps

STEP 01

Learn the Basics

Learn core concepts of production planning, including material requirements planning, capacity planning, scheduling, and shop floor control.

STEP 02

Get Hands-On Training

Work in a live SAP environment with real-time exercises on production orders, material planning, capacity scheduling, and process optimization.

STEP 03

Earn Certification & Apply Skills

Complete your SAP PP certification at TechMaax and apply your skills in production planning, manufacturing, and operations management roles with confidence.